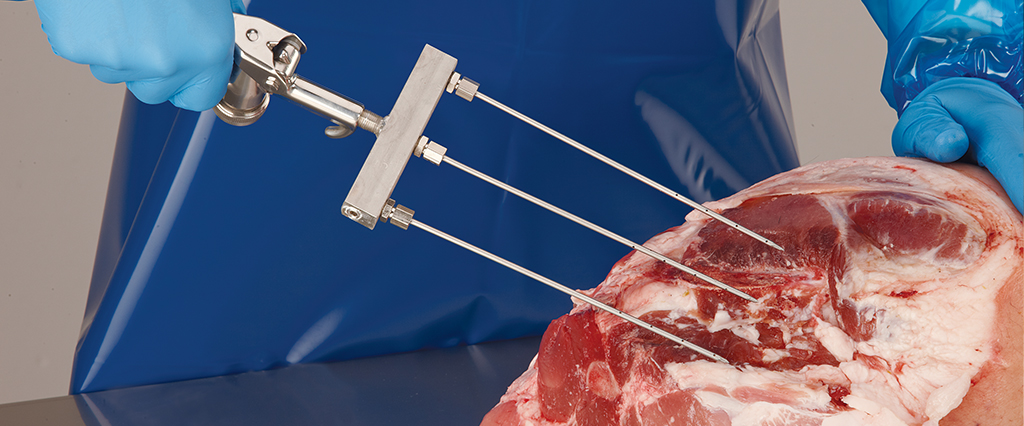

Curing for Meat Preservation

When left at room temperature, fresh meat spoils at a rapid rate, leading to changes in color, a foul smell and serious food poisoning concerns if consumed. The speed of this decomposition depends on several factors including ambient humidity, temperature and the presence of pathogens. Curing is a preservation process that helps to increase the length of time that meat remains safely edible, using the combination of salt, sugar and either nitrate or nitrite to draw moisture out of food. The decreased presence of water content in food reduces the potential for microbe growth, lowering the risk of contamination and foodborne illnesses and extending the life of the product as well as the temperature range at which it can be safely stored.

Though primarily a food preservation technique, curing can also help to infuse flavors into your product, providing a flavor profile that extends beyond seasoning alone. Bunzl Processor Division is a proud, exclusive provider of Processor’s Choice award-winning curing formulas in Hickory Smoke, Maple, Quick Salt and Sugar Curing varieties.

Processor’s Choice Dry Rub Hickory Smoke Cure

Processed from salt, sugar, dextrose, maltodextrin, sodium nitrite (.40%) and natural hickory smoke flavor.

Processor’s Choice Dry Rub Maple Cure

Processed from salt, sugar, dextrose, natural maple flavor and sodium nitrite (.40%).

Processor’s Choice Quick Salt Cure

A 6.25% sodium nitrite is fast acting for hams, sausage and other meats.

Processor’s Choice Sugar Cures

Maple Sugar, Brown Sugar or White Sugar varieties, processed from salt, sugar and a dextrose base containing sodium nitrite (.79%).

Is curing the right solution for preserving and flavoring your product? Click the icon on the bottom right corner of your screen to chat with us, or call 800-456-5624 to speak with a product specialist and learn more about our curing solutions.