Bunzl Processor Division — Your Complete Packaging Partner

Bunzl Processor Division is known in the food processing industry for providing a full line of the highest quality packaging equipment and supplies. In addition to these products, we are proud to offer our customers a variety of supportive services to ensure that you are getting the highest return from your packaging operations. Below you will find more details on how our various packaging specialists can help to support and enhance your business productivity – and prove that Bunzl Processor Division is truly your Complete Packaging Partner.

SERVICE SPECIALISTS:

SERVICE SPECIALISTS:

Our dedicated team of service specialists have over 30 years of experience troubleshooting and repairing all makes and models of rollstock, vacuum chamber and form fill seal machines. BPD can assist you with any machine problems or provide preventative maintenance to ensure that your packaging equipment is running smoothly and at the optimum level of efficiency. If your business is located within the continental United States, BPD will gladly help get your machines up and running properly. For more information, give us a call at 1-800-888-3610 to speak with one of our Packaging Specialists.WHY PERFORM PREVENTATIVE MAINTENANCE?

- Operating faster and with fewer interruptions providing quality and consistency.

- Provides higher safety standards in food safety.

- Reduction of costly repairs later.

- Detailed maintenance records as evidence of safety standards.

- Make the most of your investment.

NORMAL SERVICES PROVIDED

|

SEALING DIE TOP

|

SEALING DIE BOTTOM

|

|

TRANSPORT CHAINS

|

SEALING VACUUM VALVE

|

|

SEALING DIE LIFT

|

PRINT SPECIALISTS:

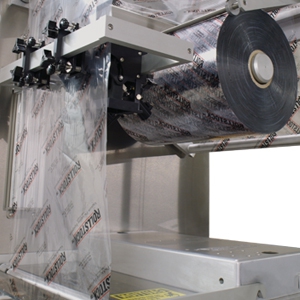

Is your product getting lost or overlooked because the plain packaging does not distinguish your product from the rest of the competition? Do regulations now require that you must print traceability information on your otherwise unprinted packaging? Are you ready to make the change from labels to printed film? We have the solutions for you! Our print specialists can help take you through the steps of transitioning from plain to printed films so your product will visually, creatively and effectively promote your business or brand name. We work directly with the printer to ensure that your graphics are in a printable format, that they meet your machine and printer specs and help guide you through the graphics and proofing processes. We also offer guidance on regulations, potential print issues and print placement. Whether you are new to printed film or have been through this process before, we are here to make sure that the transition from plain to printing packaging results in your vision coming to fruition as seamlessly as possible!MATERIAL SPECIALISTS:

Using the ideal materials for your food packaging equipment is of utmost importance in making sure your production line runs efficiently and cost effectively. Using the wrong film material or thickness can result in tears, blowouts and improper seals which will not only slow down your production line, but ultimately could ruin your product itself. Bunzl Processor Division has material specialists on staff that work with you to determine the type and thickness of film that will work best with whichever brand and model of machine you are using. Even if you are not experiencing any issues, our material specialists may still be able to help. Oftentimes, a processor’s packaging production line is running fine, but when our material specialists take a closer look, they find that the film type being used may be a little larger, or the material a little thicker, than is really needed. You may be able to get the same output using a different material that will provide the same results, but at price point that will pass along cost savings. Our food packaging experts take the time to understand your products and processes, including product shelf life. We can not only help you determine the best film FOR your production line, but they can even help find cost-savings WITHIN your production line. And those efficiencies equal savings!FREE PACKAGING CONSULTATIONS:

Not sure where to start in establishing or expanding your packaging production line? Not to worry! With over 135 years of expertise in the food processing industry, our packaging consultants are happy to set up a time to meet with you to determine your packaging needs. No business or plant is too small – we simply want to help you find the most efficient and profitable way for you to package and present your product. We’ll come to you to discuss shrink bags, vacuum pouches, cook-chill bags, shrink bags or roll stock – and together we can figure out which packaging process best fits your application!Interested in hearing more? Call us at 1-800-888-3610 to speak with one of our Packaging Specialists and learn how we can help elevate your product packaging operations today!