Caring for Your WorkHorse® Metal Mesh Gloves

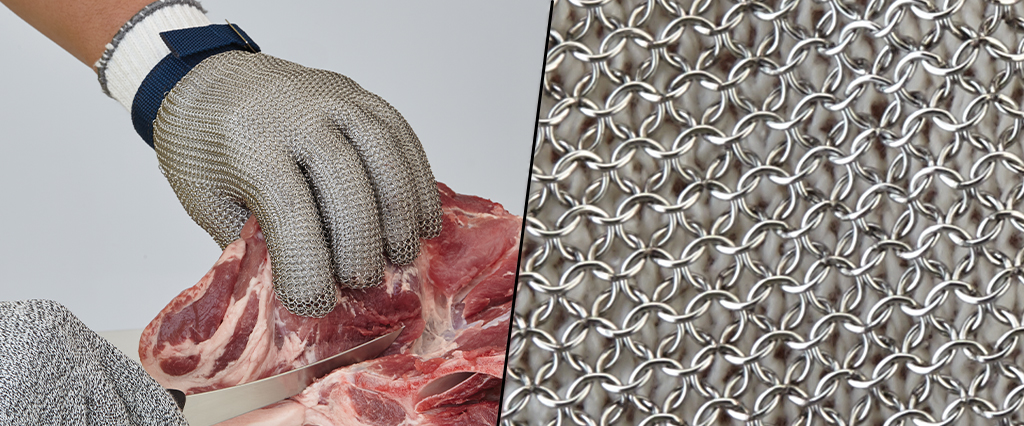

Metal Mesh Gloves are a vital form of protection in the food processing industry, helping workers to protect one of their most valuable assets – their hands. Incorporating these protective gloves into your processing operations is a valuable investment, as the average hand injury bill exceeds $6,000, with each workers’ compensation claim reaching $7,500. On top of this, indirect injury costs can include lost worker productivity, cost of training replacement employees, damage to workers’ morale and even company reputation. Investing in metal mesh glove protection is not only an investment into worker safety, but an investment into the prosperity of your company. We want to help you stretch this investment even further, by helping to maintain the condition of your metal mesh gloves and extend the life of their operation. See below for information on how to clean metal mesh gloves, recommended inspection processes and repair services to keep your metal mesh safety gear in optimal condition.

Metal Mesh Glove Cleaning

WorkHorse® Metal Mesh Gloves are easy to clean and sanitize to adhere to your facility’s hygiene standards. For food safety and contamination reasons, gloves are to be cleaned immediately after each use. Wash gloves by hand with any standard acid- and chlorine-free detergent that is approved for the food and meat processing industries. Clean, hot water up to 180°F should be used to wash and rinse each glove. After washing, gloves should be hung or suspended in a dry, well-ventilated area to ensure proper and thorough drying.

After gloves are fully dried, you may also spray with a food-safe disinfectant for further sanitation. If using disinfectant, allow it to react for several minutes. Always ensure that wet gloves are completely dried before storing to avoid damage to the glove and harboring of harmful bacteria. We recommend storing in a dry, cool and well-ventilated area any time the gloves are not in use.

Glove Maintenance

Metal mesh gloves should be inspected regularly for signs of worn links or abrasion, as damaged gloves should never be used. If a glove is found to be damaged, they should be removed from service immediately and either sent in for repair or replaced with a new glove. Note that no matter how strong, metal mesh glove links will eventually need to be repaired and/or replaced in their lifetime.

BPD Metal Mesh Repair

Should you require metal mesh repair, Bunzl Processor Division is proud to offer this service directly to help extend the life of your investment! All gloves sent in for repair are sterilized and returned with a new color-coded strap. If you are in need of this service or would like to request a quote, call our team at 800-456-5624 and we will be happy to provide more information.

Along with being the safest and most comfortable option, WorkHorse® Metal Mesh is known in the food processing industry as being the longest-lasting glove at the lowest cost. Follow the tips outlined above to get the most longevity out of this already long-lasting safety product, and enjoy peace of mind knowing that both your team and company are properly protected.