Safe Meat Processing Tips

As an industry, meat processing presents many potential hazards. Without proper procedures, equipment, and caution, meat processing is rife with opportunities for personal injury, or food contamination that can affect consumers directly.

The dangers of meat processing are preventable if you’re mindful of your equipment and procedures. To help you create a seamlessly safe meat processing environment, we’re rounding up five essential tips to hone your butchering safety:

1. Use Metal Detectable Products

Meat processing gear is the most significant contributor to contamination in the industry, and one way this can occur is when gear gets dislodged into the meat. When undetected, this puts the health and safety of consumers at risk; but it is easily preventable through the use of metal detectable gear for food safety.

Metal detectable gear usually comes in bright, easy-to-notice colors like blue to make visual detection of dislodged gear in food products easier. These products are also designed to work in tandem with standard metal detection equipment, so you don’t have to worry about missing a piece of dislodged metal after processing a cut of meat. Our metal detectable products at Bunzl Processor Division come with non-toxic metal detectable additives to make it even easier for standard equipment to detect their presence in food products.

2. Make Sanitization and Cleaning a Priority

A clean meat processing plant is a safe meat processing plant! Avoiding contamination through metal pieces in the cuts of meat is essential, but proper sanitization of your equipment before and after use is just as vital to a safe butchering process. This is textbook Food Handler’s 101, but it’s worth reiterating because cleanliness is so essential when dealing with raw meats. Your work surface, knives, gloves, and any other tools and equipment that have made contact with raw meat must be properly sanitized after use (and only used for meat processing).

A butcher’s personal hygiene matters as well, of course. Keep yourself clean and tidy, tuck away hair (and facial hair) in a hairnet or bouffant to keep it from contaminating the meat, and wash, wash, wash your hands.

3. Wear Metal Mesh Gloves and Other Personal Protective Equipment

The safety of the food processor is just as important as the safety of the consumer! You are likely to use very sharp cutlery when cutting through thick sides of beef or even trying to work around or through bone (more on this later). So personal protective equipment (PPE) is imperative.

To protect from potential injury, butchers and other meat processors should wear metal mesh gloves to keep their hands safe in the event of a slip. Metal mesh is cut-resistant and puncture-resistant, significantly reducing the chance and impact of injuries from cutlery.

Bunzl Processor Division offers our WorkHorse Cut-Resistant Gloves for an ideal PPE solution. Featuring a unique blend of high-performance fibers and stainless steel, the WorkHorse Cut Resistant Gloves offer exceptional comfort and meet all USDA food handling requirements. Resistant to acids, alkali and other organic solvents, the gloves are 100% latex and silicone free, and machine washable too.

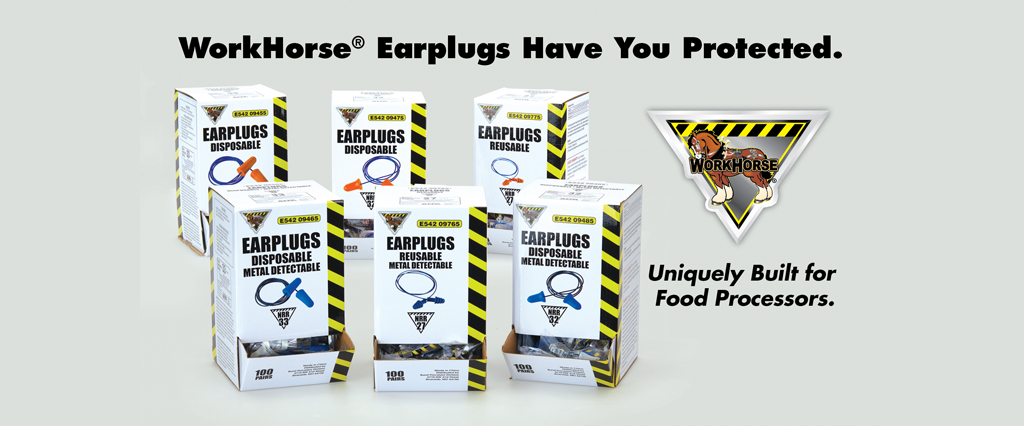

In addition to mesh gloves, metal mesh is used to create gear for upper body protection, extending protection to the arms, shoulders, and thighs. Other protective equipment you should consider for personal safety includes eye and ear protection, head protection, and anti-slip floor compound.

4. Use Sharp Cutlery

Though it may seem counterintuitive to those new to meat processing, dull knives are much more hazardous than properly sharpened cutlery. A dull butcher knife requires more effort from the butcher, which also means more force going into the motion if a slip occurs. Dull knives also slow the process and lessen the cleanness of a cut.

To keep your cutlery in tip-top shape, you should hone and sharpen it regularly (the frequency will depend on how often you use the knife in question). After years of honing and sharpening your favorite cutlery, of course, it may be time to purchase new knives to keep your butchering efficient and safe. Investing in high-quality knives means they will last you for years to come, holding their edge through constant use. Make sure every knife you have in your toolkit is sharp and ready to use so you aren’t tempted to pick up a dull blade in a pinch.

5. Ergonomics = Safety

To further improve safety conditions for butchers and other meat processors, anyone handling sharp cutlery and working with food products should use tools that are the right fit for their needs! This is why so many butchers are extremely loyal to specific knife manufacturers: once they find what works for them ergonomically, they stick with it!

Knives with an ergonomic design like our INOX Pro boning knives will increase thumb contact during inverse use, keeping your grip strong longer so you don’t tire quickly during a full day of cutting meat.

Get Equipped for Safe Meat Processing

Your safety (and the safety of your customers) matters to us, whether you’re part of a massive meat processing plant or a small local butcher shop! So give those hands a thorough washing, sharpen those knives, put on your mesh gloves and protective gear, and don’t forget to check for metal and sanitize when you’re done. Implementing these safety tips will make for a better meat processing experience for you and your customers alike.

If you’re missing any of the gear listed above (or if the gear you have is long overdue for replacing), visit us online to stock up on all your safe meat processing needs!