Zero Gravity Balancers Designed for Food Processing

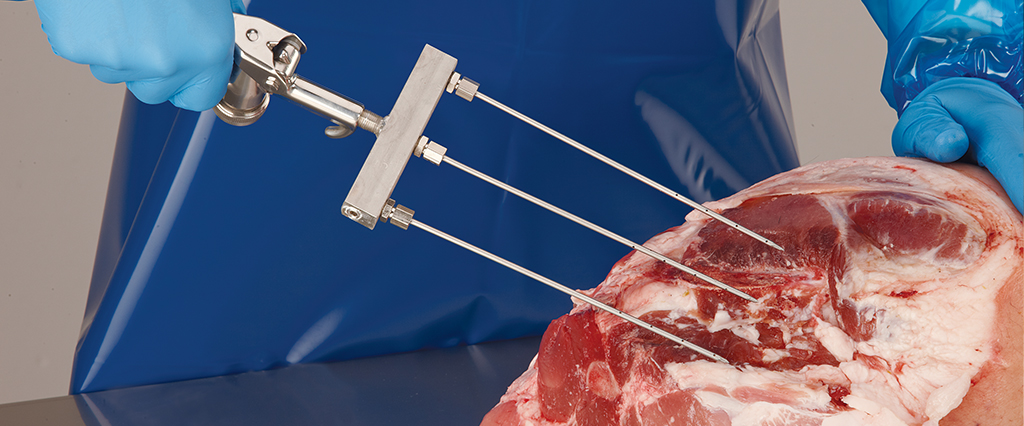

Working in a food processing plant can be tiring for workers, from using heavy materials to long hours on your feet, any form of relief is beneficial. Spring balancers are used in slaughterhouses and butcher shops to counterbalance heavy hand-held loads such as wellsaws, bandsaws and stunners. Spring balancers give the effect that the load has zero-gravity by minimizing the weight of the load for the operator. The worker does not need to apply much force while using heavy tools, since the suspended load becomes nearly weightless in their hands. This helps reduce worker fatigue, safety hazards, and tool damage while allowing for improved accuracy and production volume.

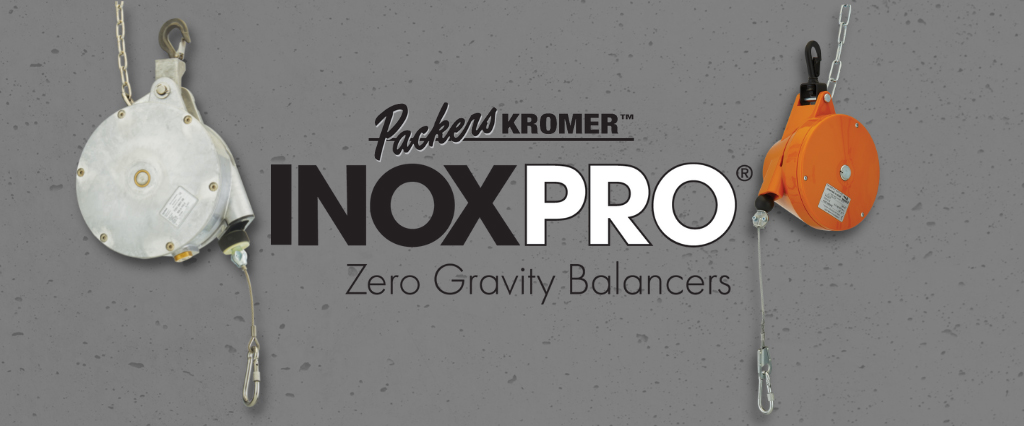

Packers Kromer™ INOX Pro® Zero Gravity Balancers are designed specifically for the food processing industry. The balancer housing is constructed of either high-impact nylon or unpainted aluminum and contains a stainless-steel top suspension and cable, which eliminates the possibility of paint chips as a foreign material and helps to keep the balancer free from corrosion. Equipment of up to 286 pounds can be used effortlessly with the proper balancer selection. When not in operation, the balancer suspends the heavy equipment and keeps it out of the way, yet within easy reach.

There are five different models available for the Packers Kromer™ INOX Pro® Zero Gravity Balancer: the 7211, 7221, 7230, 7241, and 7251. Each model is available with different load capacities and cable lengths to meet your facility’s specific needs. All models come with many beneficial features including a quick-change stainless steel cable, step-less tension adjustment, automatic safety detent, floating rotating suspension, locking safety hook and much more.

If you’re looking to enhance worker and operational efficiency in your facility, this balancer is the answer! For more information about the Packers Kromer™ INOX Pro® Zero Gravity Balancer, and to get help determining which model is right for your application, please call us at 800-456-5624 or chat with us online to discuss your facility’s specific supply needs.