Honing vs. Sharpening – Get the most out of your Knife

Whether it’s for personal or professional reasons, it is important to ensure that the knives you use are equipped with a sharp edge. The use of dull blades not only results in uneven and inefficient cuts, but can also increase chances of injuries, as they require more effort and force to cut effectively.

There are two techniques used to maintain the edge of your knife: sharpening and honing. Though they have the similar beneficial outcome of providing a sharp and effective cutting edge, these two methods differ in both practice and purpose.

To understand these procedures, it is important to understand the design of a knife’s cutting edge. The very edge of the cutting edge is actually not solid. The structure is best described as feathered. Although these ‘feathers’ are not visible to the naked eye, it’s essential that they are both present and aligned for the for the knife to function properly. During normal use the edge “wears” and become dull – this is due to these feathers either bending or pushing out of alignment. Occasionally the edge may come into contact with something hard and cause the edge to dent, damaging the feathered structure. A worn edge can usually be restored to optimal condition by honing. A damaged blade typically requires the entire cutting edge to be reshaped and repaired.

Honing

Honing is the process of realigning a blade’s edge by pushing the feathered structure of the knife back to the center. A properly honed knife will perform like new. Honing should not remove any material from the knife itself, but simply adjusts the blade’s edge to its original straight form. Knives that are properly cared for should be honed regularly. Since the honing process does not remove steel from the blade, you can hone a knife as often as you’d like, with no impact to the longevity of the cutlery. Some professionals hone before each use.

Honing is performed using a tool referred to as a honing steel, honing rod or a sharpening steel or with a device referred to as a mousetrap. These tools can be constructed of diamond, ceramic or steel, with varying diameters, surface finish, lengths and handle options. Click here to see the variety of steels that Bunzl Processor Division offers to ensure that your knife is properly honed and ready to provide superior performance.

To hone a knife, it is recommended to touch the heel of the knife (the part of the blade that is furthest away from the tip) to the top of your chosen steel at the angle your knife was sharpened at initially. This angle is critical as the goal is to align the feathered edge back to the proper cutting angle. Most processing knives are a 32°-36°, while some more specialized knives will have much sharper (18°-22°) or much more chiseled angles (closer to 40° or 42°). Once the angle is known, divide that number by 2 and hold your knife to the sharpening steel at that angle. Due to the shape of the honing steel and the hardness of its surface, only use enough pressure to make contact and hold it at that angle – more pressure than necessary will overbend the feathers. Ensuring that the steel you have selected is longer than the blade you are restoring, slide the knife down the steel with an even smooth motion. The goal is to touch the entirety of the blade’s edge to the steel with every pass. Repeat on the other side, ensuring to hone each side an equal number of times.

Sharpening

When the honing process no longer restores adequate sharpness to a knife’s edge, sharpening should be performed. The process of sharpening removes material from the blade with an abrasive material to reshape the edge. Sharpening should not be performed as routinely as honing, as it’s not only unnecessary with normal use, but will remove steel from the blade more quickly, reducing the life of the knife.

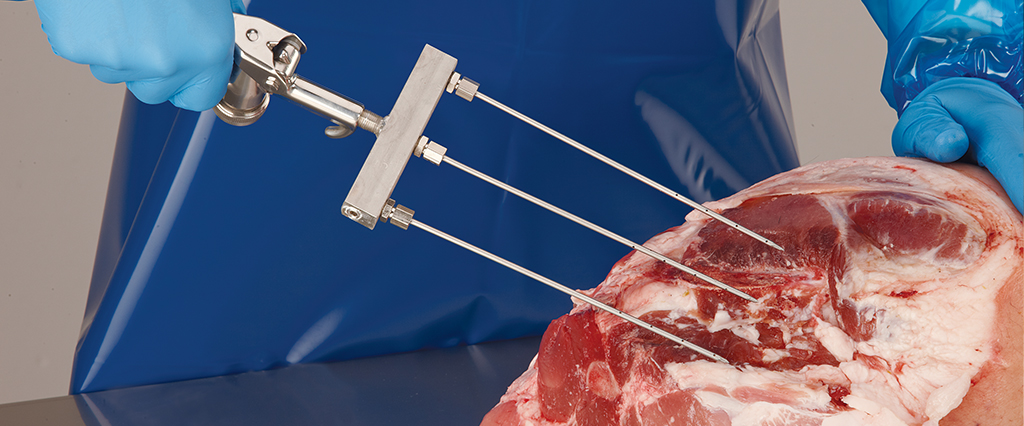

Types of knife sharpening tools vary but fall under two main categories: powered sharpeners and manual sharpeners. Powered tools are convenient and fast, but require a gentle touch to ensure proper use. Manual tools rely on the operator to provide the force and angles needed to sharpen. Both methods use an abrasive and a lubricant to keep the edge cool and to allow the required feathered structure to be properly created. Selecting a sharpening tool depends on the number of knives used and the frequency at which sharpening is necessary – along with user preference. Whatever method is chosen, it is again critical to know the angle desired, and to do everything possible not to overheat the steel. A light touch is critical to only remove a small volume of the steel and reshape the edge. Click here to shop the variety of industry-proven favorites that BPD offers.

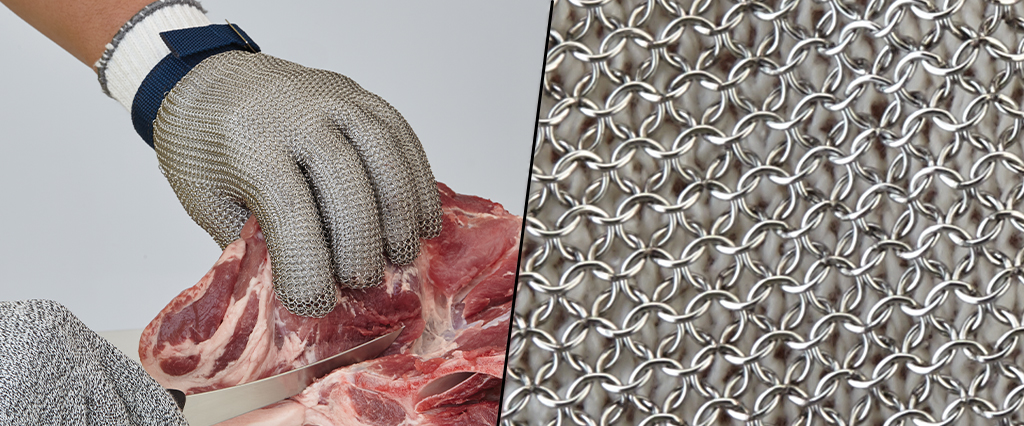

The sharpening process varies depending on the type of sharpener that you select. To ensure that you are doing so correctly, consult the sharpener’s owner’s manual or contact our team for instructions and additional best practices and always wear your PPE when sharpening a blade.

Proper knife maintenance including both honing and sharpening will extend the useful life of your knife, enhance its performance and reduce the chances of accidents and injuries resulting in cuts or repetitive motion stresses. Just as the process of using a knife within your operations is not something everyone can do on their first try – sharpening and honing take practice to develop effective and efficient methods that work for you. For more information on sharpening and honing tools, or to shop our wide offering of knives, visit us online or contact our cutlery experts at 800-456-5624.