How to Preserve Pre-Packaged Meat

Pre-packaged meat has already been through some amount of preservation, using different kinds of packaging to keep it fresh while in transportation. But as a butcher, grocer, or other food handling professional, it’s critical to ensure that pre-packaged meat stays safe and of the highest quality from your facility to the consumer’s dinner table. And the longer you store the meat and fresh game, the more significant proper packaging becomes, ensuring it remains fresh and safe to consume until you’re ready to cook and prepare it for eating. Fortunately, there are some smart strategies for helping meat and poultry last as long as possible! Let’s explore why proper preservation is so important, action plans to keep meat safe, and various packaging options to consider.

Why Does Proper Meat Storage Matter?

Meat and poultry are types of perishable food that can quickly become breeding grounds for bacteria. According to the Food and Drug Administration (FDA), any perishables left out at room temperature for two hours or more are not safe to eat and should be discarded. This is because perishable foods at room temperature enter the “danger zone” where bacteria and other pathogens can quickly develop. This zone is between 40 and 140 degrees Fahrenheit, or 4 to 60 degrees Celsius.

How to Store Pre-Packaged Meat

Here are the most common methods for preserving pre-packaged meat and how long you can expect your meat to last with each method.

Refrigeration

The most common way to preserve pre-packaged meat is through refrigeration. This method of meat and poultry storage is the simplest, but the length of time meat will stay high-quality depends on the product. Here is the average shelf life for different meats when stored in secure packaging and refrigerated at 40°F (4°C):

- Ground Meat and Poultry: 1 to 2 days

- Beef, Veal, Lamb, and Pork: 3 to 5 days

- Ham: 3 to 5 days

- Bacon and Sausage: 1 week

- Fresh Poultry: 1 to 2 days

- Fish: 1 to 3 days

How to Store Pre-packaged Meat in the Refrigerator

Once pre-packaged food is opened, it’s more susceptible to contamination. Depending on the kind of meat, various kinds of flexible packaging solutions can be used. These are appropriate if you’re re-packaging for consumer sales; in conjunction with a marinade or a spice, rub, or seasoning; or for use in other products in your facility.

Freezing

Meat and poultry last much longer when frozen and stored at 0°F (-18°C) because the below-freezing environment is much less hospitable to pathogens and bacterial growth. This makes freezing an ideal method for keeping pre-packaged meat and poultry safe for consumers for a longer timeline. Here is how long various meats and poultry last when properly frozen:

- Ground Meat and Poultry: 3 to 4 months

- Beef, Veal, Lamb, and Pork: 4 to 12 months

- Ham: 6 months

- Bacon and Sausage: 1 to 2 months

- Fresh Poultry: 9 months to 1 year

- Fish: 2-8 months (varies greatly depending on type of fish)

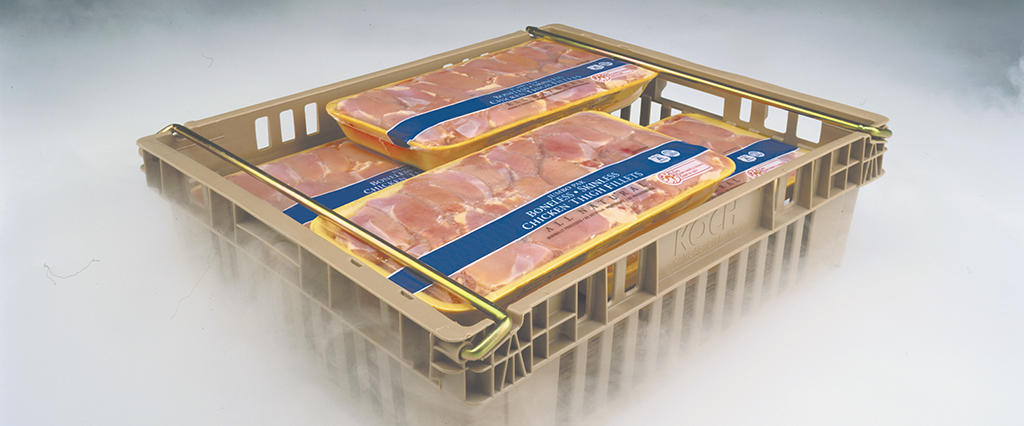

How to Store Pre-packaged Meat in the Freezer

In addition to protecting pre-packaged meat from contamination, you’ll also need to protect meat from the rough conditions of freezers. While freezing will keep meat safe, you’ll run the risk of the dreaded “freezer burn.” Freezer burn happens when foods are exposed to cold, dry air. This causes them to dehydrate as their outer layers lose moisture. The result? Dry, tough, tasteless cuts of meat! The answer? Secure, freezer-friendly packaging!

With the right flexible packaging solutions, you can keep pre-packaged meat both safe and tasty. The right packaging solution is dependent on quantity, ideal use timeline, and where the meat is headed next (like consumer sales, using in other products, or distributing through different channels). Even if freezer storage is very short-term, freezer bags are designed with a thicker plastic material that is more protective and durable in long-term freezer storage, making them an ideal choice.

Packaging Solutions for Pre-packaged Meat: Refrigerator and Freezer

Once pre-packaged food is opened, it’s more susceptible to contamination — which makes flexible packaging solutions so integral to your facility’s operations. These are appropriate if you’re re-packaging for consumer sales, for use in other products in your facility, or other distribution methods.

Bunzl Processor Division offers a variety of options to preserve pre-packaged meat, including:

Bunzl Processor Division is the exclusive distributor of the Clarity® line of vacuum pouches. These pouches are constructed of high-quality co-extruded cast film, and contain no BPA, Melamine, starches, or animal by-products. Because of a powerful sealant, both meat handlers and consumers can handle the pouch without weakening it, which results in fewer punctures or tears. And since they’re easy to fill, vacuum pouches will help increase the speed of your packaging procedures.

Shrink bags are available for a wide range of products, including different sizes and cuts of meat. Particularly for that Cryovac® case-ready look, choose shrink bags by the case or available in smaller Smart Packs. Custom-printed shrink bags are also available from Bunzl Processor Division for the branded look customers will reach for.

We offer both forming and non-forming films, all available in clear, black, random printed, or custom printed. There’s no minimum order size, so you’re free to order as much or as little rollstock film as you need, when you need it.

All of our bags are constructed of tough, two-mil polyethylene – making them resistant to punctures, rips, and tears. In addition, our food bags feature Safe Handling Instruction panels, both for consumer and non-consumer use.

Cook Chill bags are perfect for pre-packaged foods of pumpable consistency, such as soups, chowders, sauces, gravies, gelatins, chili, stews, pasta dishes, pizza toppings, and many more. Foods are cooked and prepared at peak quality, and then bagged, sealed, and chilled to maintain quality. Because of their superior durability, cook chill bags result in a longer product life and improved sanitation.

At Bunzl Processor Division, our shrink film has a premium resin formulation that provides our strongest seals and offers a high shrink force. This makes it an ideal choice for multi-packing and unitizing pre-packaged meats. Furthermore, shrink film’s superior sealing performance saves time and money on expensive rewraps. It even performs well on older equipment, so you can feel confident no matter what. Bonus? It’s fully recyclable!

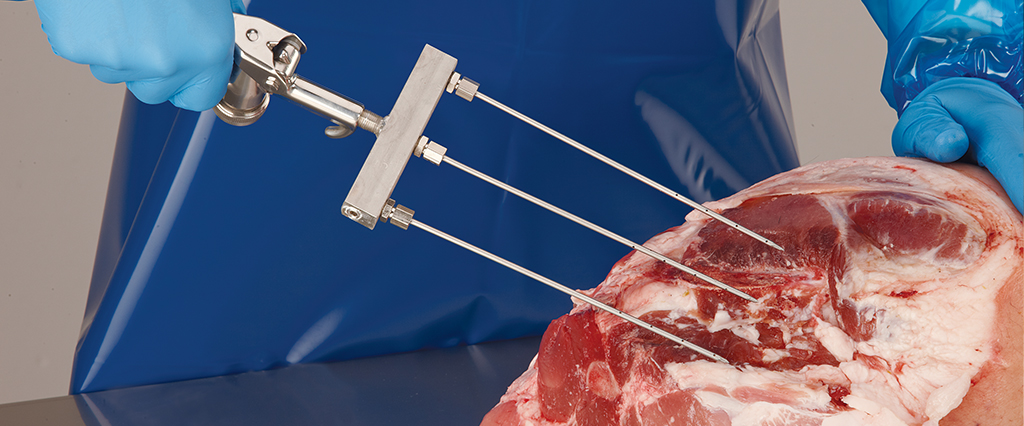

The right equipment is paramount for smart storage too. Depending on the method you select, your facility may consider a vacuum packing machine or bag closures as complementary equipment to the storage supplies. Our experienced sales staff has extensive knowledge of the food processing industry, and can suggest and customize the packaging system that works best for your application.

Stock Up on Meat Processing and Packing Essentials!

Bunzl has a full store of the best quality meat processing equipment and packaging materials on the market to help you safely prepare your meat at every stage. View our catalog here to learn more.