How to Ensure Your Meat Processing is Sanitary

Meat processing can get messy, presenting health and safety hazards to food handling staff and anyone purchasing meat products from a facility. For this reason, meat and poultry processing plants of any size are required to adhere to strict federal regulations, including regular USDA inspections.

To keep your meat processing facility in line with regulations and as sanitary as possible, it’s crucial to understand the health risks of ignoring these standards — and what you should do to prevent contamination and disease in your products.

Health Risks from Unsanitary Meat Processing

Food handling, in general, has a lot of risk for cross-contamination. And meat processing is among the most hazardous. Some potential risks of an unsanitary meat processing environment include:

- Fall or slip hazards for employees

- Cross-contamination with non-meat food products (or even among different meat products)

- High risk of food poisoning and other illnesses from various bacteria

- Spread of illness from employees to consumers through meat products

Safe meat processing requires high levels of frequent cleaning, inspection, and sanitization to eliminate risks to both employees and consumers. This process should be intentional, strategic, and established right from the start to develop solutions that work for your specific facility. Creating a HACCP plan can help you develop and improve a sanitization process and implement better quality control across the board, but in general, you can follow six broad steps for a full and thorough sanitation of your facility.

Step-by-Step Sanitization for a Meat Processing Facility

Completely cleaning your entire meat processing plant can take as much as a full eight-hour shift to complete, especially if your plant is large or your number of employees is small. Here are the six steps to a typical sanitization process for a meat processing facility:

1. “Lock Out”

Also known as “tag out,” this first step involves making sure all equipment is unplugged, disassembled, or otherwise locked down in a way that protects janitorial staff from the risk of injury while the equipment and facility are being washed. As the equipment is locked down, employees should clean the equipment of any food particles, product debris, and other larger contaminants that can be handled prior to rinsing and washing.

2. Pre-Rinse

Once the equipment is safe for sanitizing and major contaminants have been removed, it’s time for a pre-rinse! During this phase of the sanitization process, equipment is hosed down with hot water to remove any remaining visible particles and debris.

3. Soap and Scrub

With the equipment inspected and rinsed, the sanitizing can begin. The “soap and scrub” phase is where every single area of the facility—floors, walls, equipment, and tables—is covered in a foam cleaning agent and scrubbed thoroughly. Floor drains are usually scrubbed clean with separate brushes and cleaners as well to ensure proper drainage before moving to the next step.

4. Flood Rinse

After soap and scrub, employees should rinse everything with hot water once more to clear away all of the foamy residue, as this can also be a contaminant to the meat itself that will be processed later on in the facility.

5. Inspection

The sanitization may be done, but it is always good practice to ensure you did not miss a spot! Employees should inspect all surfaces and equipment for any remaining food particles or debris, along with slick or oily surfaces that require further cleaning. They should also make sure all foam and cleaning agents have been effectively rinsed away.

6. Reassembly

If all looks spick and span, employees are safe to return equipment to ready-to-use status. Equipment should be set up just as it was before lockout—but cleaner. Before they do so, employees should change into fresh clothes or remove the protective outer layer of cleaning gear so they do not risk recontaminating the freshly cleansed facility.

Meat Processing Sanitation Supplies

Cleaning a meat processing plant of any size requires certain sanitation supplies, as well as the right gear to keep everything safe and sterile between cleanings. Here are the essentials you should stock your meat processing facility with:

Industrial Grade Washdown Equipment

Choose industrial-grade washdown equipment that is made for hot temperatures and highly durable. Our portable foam units are available in 10- and 20-gallon sizes and come with a large drain in the front of the tank, an inline strainer for debris protection, and an extra-long foam hose. If you prefer a smaller foam spraying option, a couple of these handheld industrial foamer units are just the thing for smaller butcher shops. In addition to foamers, you should be well equipped with spray nozzles and hoses that can handle high heat for the pre-rinse and flood rinse phases.

Squeegees and Scrubbers

You will need a variety of squeegees and scrubbers for properly cleaning each surface of your meat processing facility. For set-in contaminants and hard-to-deal-with debris, scrub brushes and scouring pads will be your best friend. You may also want a scraper for when all else fails.

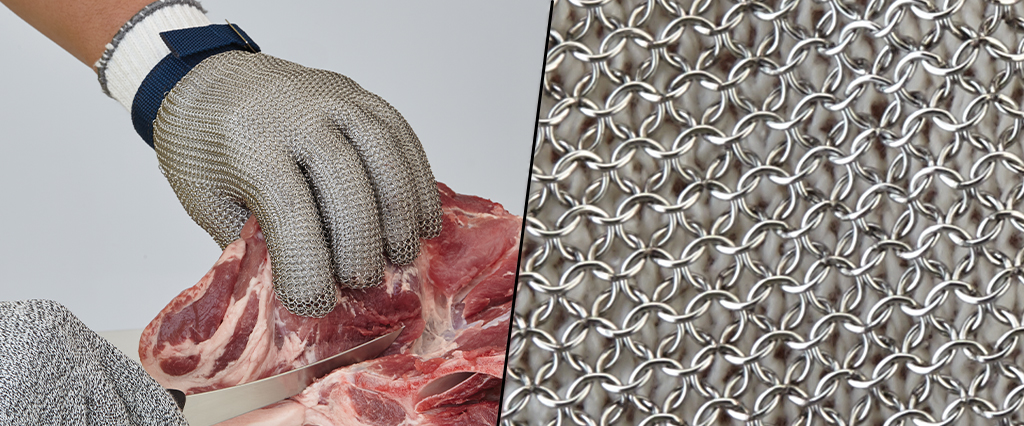

Food-Safe Protective Clothing

Employees should always wear food-safe protective clothing whether they are handling meat products or cleaning the facility. This includes all the basics such as gloves and aprons. Employees should also use hair guards to reduce cross-contamination and may require more full-body coverage through gowns, sleeves or rain gear, instead of just an apron, particularly when cleaning in order to protect their base layer of clothing.

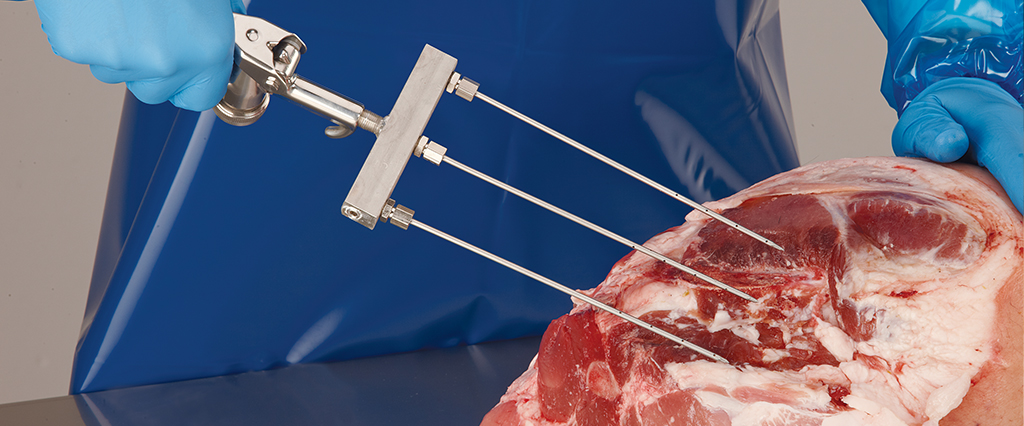

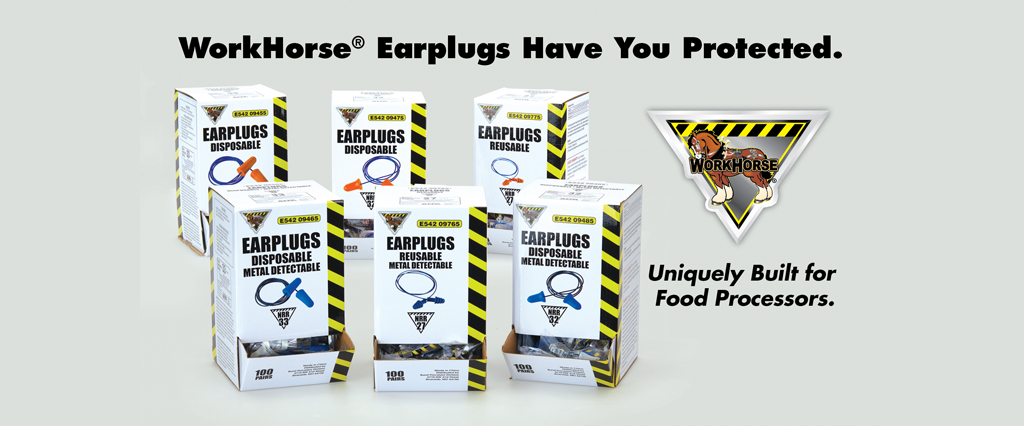

High-Quality Meat Processing Gear

While not directly related to sanitization or cross-contamination prevention, high-quality meat processing gear can significantly reduce the risk of contamination occurring in the first place! This is especially true of metal detectable gear that helps prevent foreign object contamination in meat products, keeping your food safe throughout processing and all the way to the consumer’s kitchen.

Set Your Facility Up for Success with Bunzl’s Sanitation Supplies!

At Bunzl Processing Division, we have everything your facility needs to maintain a healthy, safe, and sanitary environment for people and products alike. Our team of meat processing experts is ready to help you create a plan that keeps your facility in line with federal regulations and maintains the highest standards of cleanliness in the industry. View our catalog online or contact us for help creating your sanitation plan!