What Kind of Quality Control Does a Meat Processing Plant Need?

Quality control for meat processing plants is essential for food safety best practices. The meat industry faces many unique challenges to food safety because of ever-evolving food regulations and safety standards. To ensure food safety in a meat processing plant, it’s important to integrate quality assurance practices throughout the supply chain, from breeding and processing to packaging and distribution.

Meat products are the largest source of protein-rich foods in the food industry but are also at significantly higher risk for quality control issues. From hazards to workers within a meat processing plant to foodborne illnesses from improper hygiene or packing procedures, quality control for meat processing plants is essential for combatting these risk factors. Meat processing plants should follow a Hazard Analysis Critical Control Point (HACCP) plan to ensure the best possible quality control.

What is a HACCP Plan?

HACCP guidelines, as outlined by the Food Safety and Inspection Service (FSIS), exist to help small food processing establishments prevent food safety problems by preventing, controlling, eliminating, or reducing hazards in the food production process. Creating a HACCP plan involves moving through a scientific process with seven principles to adequately address hazards and create a safe meat processing environment.

Here are the seven principles and everything you need to know to begin implementing your own HACCP plan for proper quality control:

1. Conduct a Hazard Analysis

The first step is to identify food safety hazards likely to occur before, during, or after entry into the meat processing plant. These hazards will fall into three categories:

- Biological Hazards that make food unsafe to eat, such as bacteria, parasites, and viruses

- Chemical Hazards naturally occurring in foods, added during meat processing, or administered to livestock before slaughter, also including cross-contamination of allergens that could be hazardous to some consumers

- Physical Hazards are those which may injure the person consuming the product, such as foreign materials (glass, metal, or bone in a boneless cut) in meat that has been processed, packaged, and purchased

These hazards may occur due to cross-contamination, unidentified bacteria within livestock before slaughter, improper storage conditions, or other failures in the quality control process. Once you’ve identified a potential hazard, you must determine how likely that hazard is to occur within your meat processing plant and the severity of the risk to consumers.

2. Identify Critical Control Points

A Critical Control Point (CCP) is a specific point in the food production process where steps can be taken to prevent, eliminate, or reduce food safety hazards. Some common CCPs include:

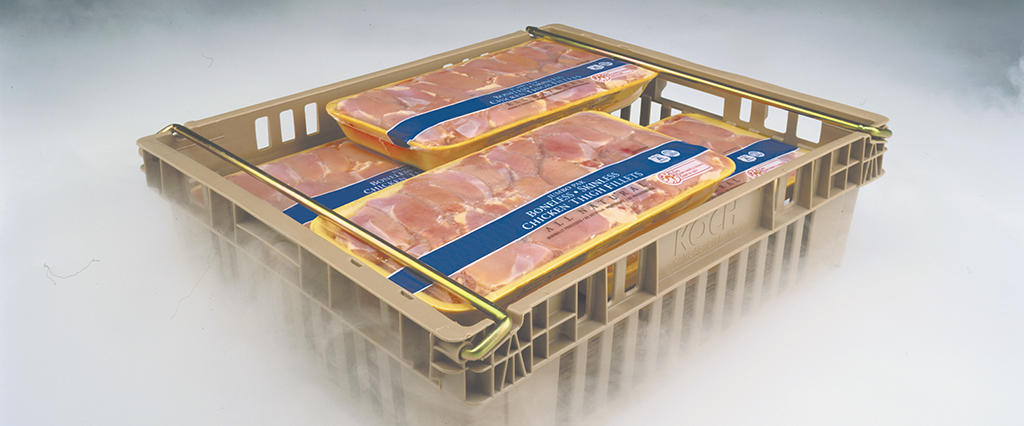

- Chilling storage temperatures to minimize biological hazards

- Cooking to specific temperatures to kill biological hazards

- Sanitary slaughter procedures and antimicrobial methods to prevent or reduce the presence of chemical and biological hazards

- Testing products for chemical hazards

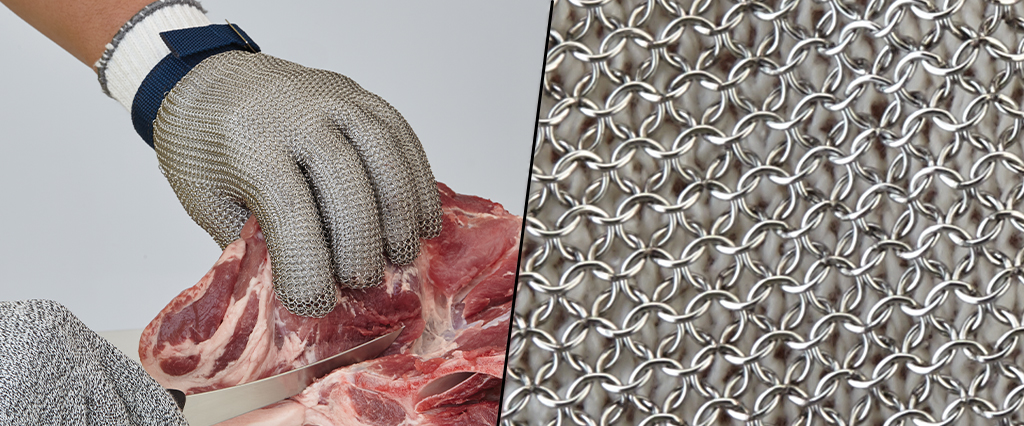

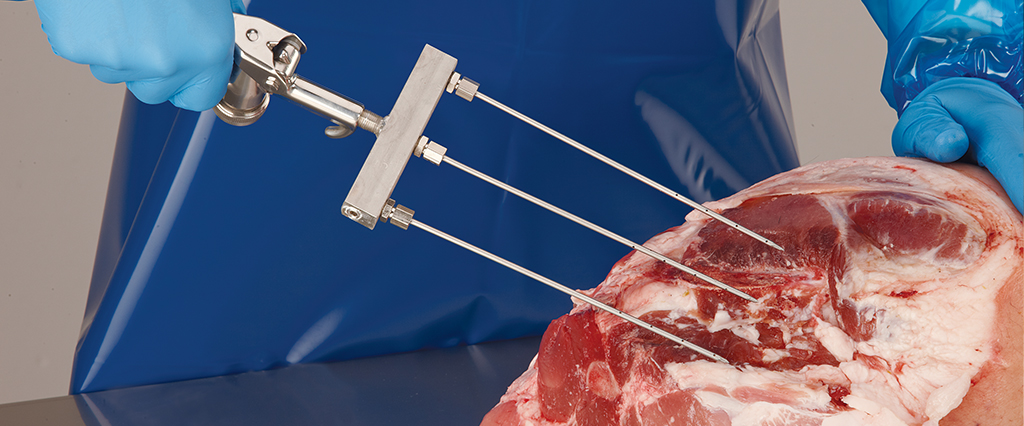

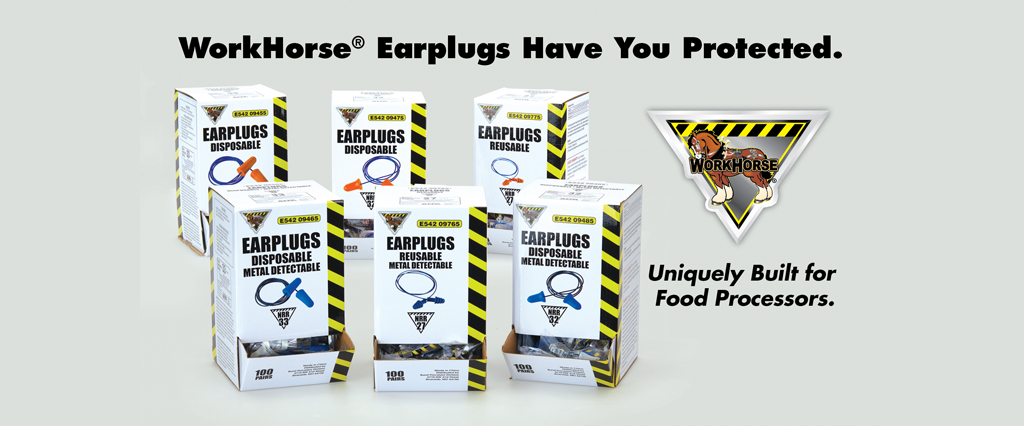

- Scanning products for contaminants or physical hazards and using metal detectable gear

3. Establish Critical Limits for CCPs

After creating a plan to address hazards at CCPs, you must set clear criteria to demonstrate effective control of a potential hazard. This criteria typically includes an observable reading, like a temperature, time, or chemical property. At the same time, this criteria also includes limitations that keep control measures from getting excessive (i.e., a set minimum temperature so you don’t ruin your products, and a set maximum for preventing pathogen growth).

4. Establish Monitoring Procedures

With CCPs outlined and limits set, you now need to establish processes for monitoring food safety procedures in your meat processing plant. Make these procedures routine quality assurance checks performed by either employees or automated systems, recording critical limits and ensuring hazards are continually being prevented, reduced, or eliminated. This monitoring should keep track of your entire process — from slaughter to packaging — and alert you when controls fail, plus document all successes and deviations to verify quality control.

5. Establish Corrective Actions

When monitoring procedures reveal failures or deviations from the set food safety parameters, you should have a plan to correct the issue as quickly as possible and avoid the growth of potential hazards. When a deviation occurs, your corrective actions should:

- Identify what caused the failure and eliminate the issue

- Ensure the CCP is under control again

- Prevent future failures at this point in the process

- And make sure no faulty products have been shipped to consumers

If any potentially hazardous products have made their way into the market, this is when a recall must occur to protect consumers from potential risk.

6. Establish Verification Procedures

A proper HACCP plan doesn’t just get set up once and left to its own devices. You must consistently verify that the plan works correctly to prevent, reduce, or eliminate hazards and create effective quality control for your meat processing plant. These verifications differ from monitoring as they involve testing critical operational parameters, calibrating systems, reviewing records, and identifying large-scale changes to the HACCP plan if needed.

Verification cycles through three phases to keep your HACCP system in peak performance:

- Initial validation for 90 days after an HACCP system is created or revised

- Ongoing verification performed regularly to make sure the HACCP plan is successful

- Reassessment annually or whenever changes occur that alter the hazard analysis or HACCP plan as a whole

If reassessment results in necessary changes to the HACCP plan, the process must start again with initial validation to create a new procedure to address new risk factors.

7. Establish Recordkeeping Procedures

Your HACCP plan should always include detailed recordkeeping. Why? Records provide tangible evidence of your procedures and attentiveness to food safety. These records become essential in case something goes awry, like a deviation or failure requiring corrective action. Your records can help trace a problem back to the source and determine what processes and products have been affected. Most importantly, your records protect you and the ultimate consumers.

Equip Your Meat Processing Plant for Success

To guarantee optimal quality control for your meat processing plant, you need the proper equipment to process your meat and manage quality control. Bunzl Processor Division offers everything that meat processors need to support a strategic HACCP plan and keep their plant safely serving consumers with high-quality products. Our team is committed to your success, which is why we offer personalized, on-site training from experts to help you develop top-tier food safety procedures.

View our complete catalog to learn more about how our products can serve your production.