Which Material is Best for Meat Processing and Packaging?

Every meat processor — from small, local butcher shops to large, national chains — knows how important packaging materials are for safe, effective packaging. And every meat processing business will agree that a quality product with an extended shelf life is the name of the game.

Because meat products require varying degrees of shelf life and aesthetic retail appearance depending on the type of meat processor, each level of processor needs to know what meat packaging supplies are right for where they are now and what will help them move to the next level of innovation. Which material is best for meat processing and packaging? Let’s explore.

Meat Packaging Supplies for Standard Butcher Shops

Standard small or local butcher shops typically buy primal cuts, which they work into individual cuts in the back room before displaying in a storefront case for customers to choose from. Standard butcher shops aren’t working with massive amounts of product or shipping meat after it enters their store, so their shelf life needs are not quite as extensive as larger meat processors. Because their products are displayed, retail appeal is important to consider with their packaging as well.

Given these packaging needs, standard butcher shops tend to utilize meat wrap with a non-barrier structure that encompasses the meat and holds in some moisture while keeping airflow really tight for a bright red meat product. This product is expected to be sold within three days, so the packaging doesn’t need to be significantly thick or have a barrier structure.

How Standard Butcher Shops Can Innovate Meat Packaging:

When standard butcher shops grind their meat, they usually will package this in a hand-stuffed meat bag that may have some branding for retail purposes. This is the perfect step in the process for these butcher shops to improve and innovate by upgrading to a poly casing with some level of motor-driven casing stuffer, taking them from the slow hand-packing to a much faster, more efficient method.

Meat Packaging Supplies for Restaurant Sales

At the next level of meat processing are brands that process and package meat for restaurants. Because these meat products aren’t being displayed for consumer purchase, the packaging doesn’t require the same level of aesthetic appeal as it does for local butcher shops, but it does need a much more extended shelf life to distribute frozen or fresh meats over long distances.

To keep the meat protected, temperature-controlled, and fresh throughout its distribution journey, meat processors for restaurant sales use thermal forming rollstock to tightly package their products. At Bunzl, our rollstock is all Clarity™ brand because it is simply the best on the market, with excellent clarity and the longest shelf life on the market thanks to the 11-layer co-extruded design.

Meat Packaging Supplies for Retail Sales

When the pandemic hit in 2020 and restaurants shut down, many restaurant sales brands shifted their focus toward retail, as grocery stores were in need of more protein and meat processors had the protein to sell. This also meant revisiting the meat packaging methods, as retail requires next-level quality to account for consumer interaction with the product.

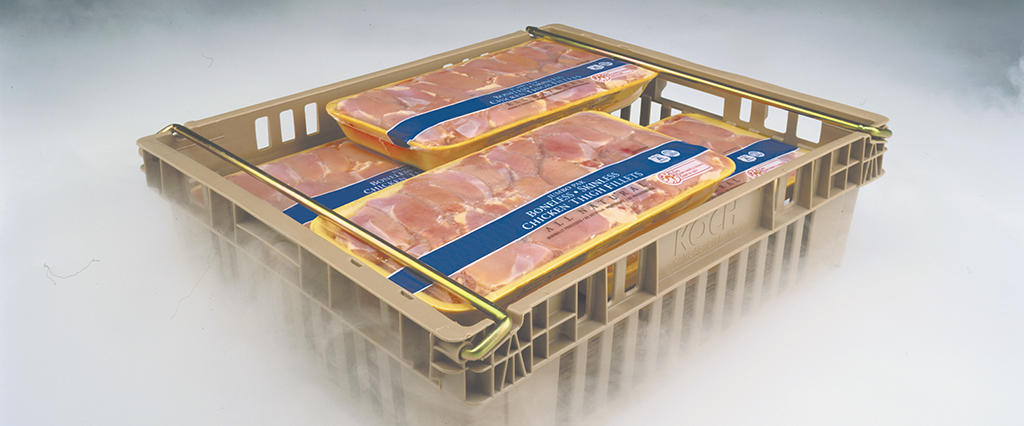

Retail meat products require the best of both worlds. Their products should be well protected for extended shelf life while also having an aesthetic appearance and effective branding to catch the consumer's eye. This is especially important with the increasing popularity of pre-made meals in retail food stores.

The best meat packaging product for retail sales is without a doubt vacuum-skin packaging (VSP) film. VSP film has a comparable shelf life to rollstock but presents a package that looks like a tray with a skin film on top that showcases the meat product standing out in the packaging. This gives the consumers a much more direct interaction with the product as they shop for their protein at the local grocer.

Although VSP film has been in short supply for the last two years because of the heightened demand, Bunzl has always maintained a strong supply chain to support our customers’ meat packaging supply needs!

Meat Packaging Supplies for National Brands

When it comes to meat packaging supplies, the largest meat processors swear by lidding film, which is a very broad and complex category of food packaging. Lidding film can be as simple as the little foil seal on your yogurt cup or that dome film over a meat tray you find at a large box grocery store.

National meat processing brands require extremely long shelf life for distribution as their meat products travel all over the country to stock their customers’ stores. Bunzl’s anti-fog lidding films have a high barrier that allows meat to maintain its red color on the inside through a combination of a tight seal and a gas mix that further protects the meat.

Bunzl is Here to Help with All Your Meat Processing and Packaging Needs!

Meat processing needs don’t start and end with your packaging supplies, which is why we at Bunzl pride ourselves on being a well-respected leader in the food processing and packaging industry over the last 140 years. With more than 10,000 supply items across 14 distribution centers, meat processors of all sizes can find the supplies and support they need at Bunzl.

Check out our complete meat processing and packaging categories to order your next round of supplies and visit our YouTube channel for our top food packaging tips.