Guide to Freezing Meat After Processing

Safe and proper cold storage of your fresh cuts is just as important as processing the meat. Freezing meat the right way will protect it against freezer burn and help it last longer, and wearing the right gear — from insulating coats to freezer boots — will ensure the whole process is as safe and productive as possible.

Of course, your cold storage needs will vary depending on the size of your operation and where your customer is located. A local butcher shop’s cold storage needs won’t be as extreme as a massive meat processing plant with customers nationwide. Let’s explore the necessary personal protective equipment for butchers and employees and safety procedures for freezing meat, as well as how to freeze the meat based on your size and customers.

1. Wear Personal Protective Equipment

When it comes to cold storage, personal protective equipment (PPE) should be a top priority! This final phase of meat processing is essential to the longevity of your products, but it can involve workers spending a lot of time in very frigid temperatures. Here’s a breakdown of all the essential PPE for a safe cold storage environment:

Freezer Boots

Freezer boots will not only keep your feet warm, but they’ll also protect you from slipping and falling due to the slick freezer floors and potential ice or water in the environment. Dunlop Purofort Thermo+ Insulated Freezer Safety Boots have a slip-resistant cleated outsole and are insulated to protect against temperatures as low as -50°C/-58°F to keep feet warm.

If you already have a pair of boots you prefer to use around the butcher shop, you can wear thermal boot socks or add insulated liners instead, though this may not be as effective if you spend several hours in cold storage. To avoid slick boots, wear boot covers in the slaughterhouse and remove them before entering the freezer area.

Insulated Clothing

Warm clothing is more than just bringing your winter coat into work, as that likely isn’t the most effective gear for working in meat processing and moving around in cold storage. Here are some things to consider when selecting protective cold storage clothing:

- Bright yellows or oranges will stand out better and improve visibility, which is especially important in a large cold storage warehouse.

- Wearing multiple layers will provide better insulation than a single jacket.

- Zippers with an additional front closure insulate better than snaps.

- It’s good to have a spare set available in case one gets wet or dirty.

- Have a moisture-wicking base layer against the skin, because you may sweat if you do a lot of labor in a cold storage environment!

For a good basic cold storage coat, we recommend this quilt-lined insulated chore coat that’s made with 100% cotton duck and insulated with premium quilt lining. If you require more full-body coverage to spend several hours in a large cold storage warehouse, these insulated separates come with a high-back bib and elasticized waist. This offers added warmth and protection to your vitals and insulation everywhere it matters, including the deep pockets!

Warm Headgear

Keeping your head and ears warm can be as simple as wearing a thick knit beanie, but this won’t add insulation and warmth to the rest of your face and neck. Full-time cold storage workers may prefer a balaclava or knit face mask to keep them cozy in such a chilly environment. For the best possible insulation on your head, try this quilted face mask!

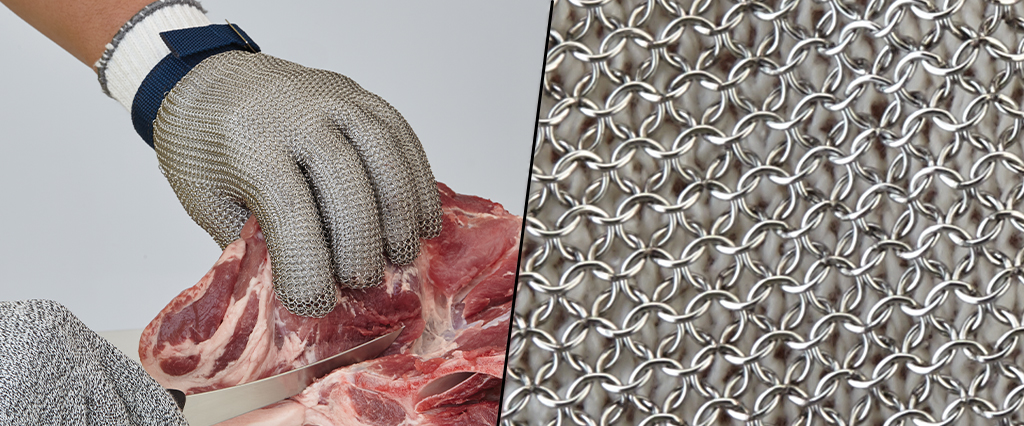

Work Gloves

Hands can get cold fast when working in cold storage, which is especially problematic as you need them to perform your duties efficiently. While thick winter gloves may keep your hands warm, they’re not ideal for dexterity. Cold storage work gloves should strike the perfect balance of insulated warmth and flexible functionality.

To keep your hands warm, start with thermal knit insulating gloves that are slim enough for hand dexterity while still providing subzero temperature protection and moisture-wicking properties. When you need another layer of warmth, add a pair of leather work gloves over the knit pair.

2. Practice Safety Procedures

Safety when working in cold storage extends beyond wearing the right gear. While personal protective equipment will keep workers warm, it can only go so far without taking essential safety precautions! To keep yourself and your employees safe while working in cold storage:

- Limit time spent in cold storage as much as possible (and set time limits, requiring workers to take breaks from frigid temperatures regularly).

- Make sure all cold storage internal doors are functioning properly so no one gets locked inside.

- Install emergency alarms in all walk-in freezers and cold storage warehouses.

- Have communication systems and procedures in place, and have employees work in pairs.

- Provide employees with PPE instead of requiring them to purchase it.

- Train all workers in safety and emergency procedures, and run quarterly drills to test the effectiveness of these processes.

3. Freeze the Meat

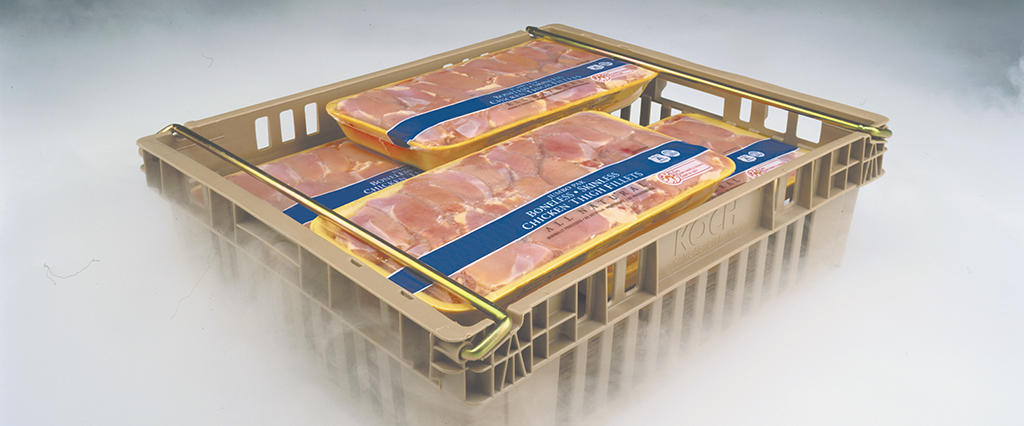

With cold storage workers properly outfitted and safety procedures in place, it’s time to focus on the purpose behind all this cold storage complexity: freezing meat! Not all meat should be packed and stored in the same way, and the level of protective packaging needed depends on how long you need the shelf life to be.

Not All Meats Freeze Equally

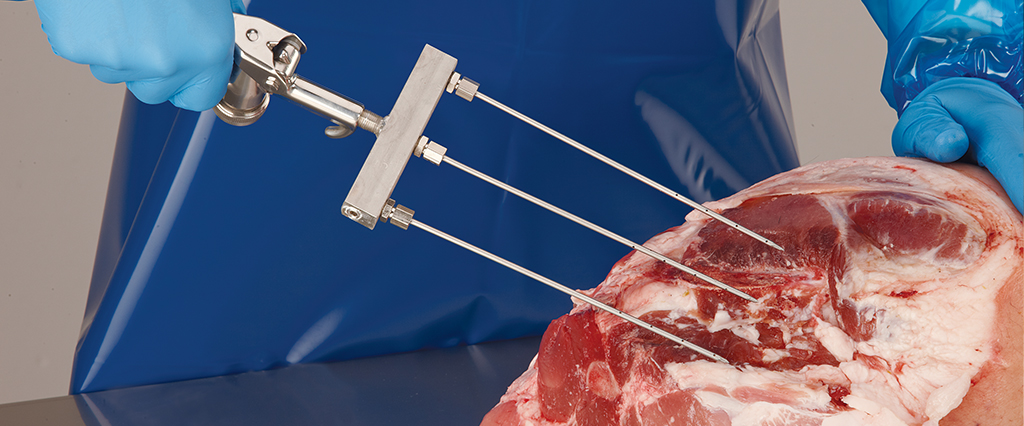

Varying types of protein have unique freezing needs, such as individual quick freezing (IQF) techniques for bulk pack chicken and fish before packing in poly or controlled vacuum packaging (CVP) lined boxes. Family sized packaging for frozen proteins use individually wrapped separation between pieces using poly sheeting, or interleaved waxed paper, and can be vacuumed packaged or wrapped in freezer paper. Fish is held in water to be frozen into ice to save off freezer burn, and frozen beef products are suggested to be consumed within 6 months after freezing for maximizing flavor profiles.

To guarantee a quality, fresh product right out of the freezer, make sure you know the shelf life and freezing needs of the meat you’re packaging, and label products accordingly to inform customers. When dealing with fish, please make sure to thaw properly. Do not thaw raw fish in a vacuum sealed package, always cut the package open prior to thawing in order to reduce the risk of foodborne illness.

Wrap Meat with Airtight Seal

Regardless of the specific product, all meat should be packaged with an airtight seal for the longest shelf life, using freezer paper or a vacuum sealer to prevent air exposure that may brown the meat or cause freezer burn. You’ll get the most effective seal from vacuum sealing with layers of polyethylene and nylon, which provide an excellent barrier while keeping the meat visible through the packaging.

Ensure Controlled Temperatures

Regulating cold storage temperatures is essential for keeping your products from defrosting or forming large ice crystals along the surface. Calibrate your thermometer at least once a year—it only takes a few minutes and is much better than the alternative of losing a lot of product to a faulty thermometer. The cold storage temperature should be at most 0°F (-17.78°C) to freeze meat quickly and maintain its quality.

Shop All Your Meat Freezing Needs

Bunzl Processor Division has everything you need to keep cold storage workers and your products safe in freezing temperatures. For the highest quality FDA-approved products and safety you can trust, shop our full suite of meat processing products or contact us and one of our expert associates will help you create a plan for processing and freezing your meat.